Vacuum and Pressure Forming

Overview

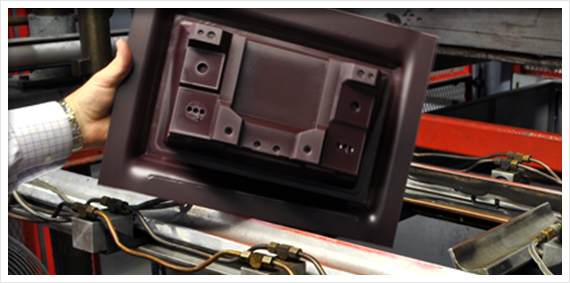

Our manufacturing partner General Plastics specializes in vacuum-formed and pressure-formed resin parts. They provide components to many industries including transportation, medical, and railway!

Owner of General Plastics, Bob Porsche, has always held a firm belief that having equipment with the latest technology is critical to his company’s success. In 2016, they were able to expand by 42,000 sq ft and now maintain dedicated assembly areas throughout the facility. GP is also ISO 9001 & 14000 (environmentally) certified.

Vacuum and pressure forming capabilities include:

- Capacity 6′ x 10′

- Parts up to 8’ x 10’ & ½” thick

- Thermoplastics include FR/ABS, ABS, Kydex, HIPS, HDPE,

- LDPE, PP, PETG and Polycarbonate

- Use of both engineering and commodity-grade materials

- Heat Bending

- CNC and Robotic Routing

Some of the benefits of vacuum and pressure forming are low cost tooling with a short lead time, and quick, low-cost tool and part modifications.

Contact Holmes-Gustafson & Associates at (815) 985-5116 and let us advise you on the best process for your desired parts!